HID Tube/LED Tube Minimum Order: 300 pcs.

15% Price Discount

Factory-direct company, with costs reduced by 15%+

50% Faster Response

From R&D to shipment, response time accelerated by 50%

100% Quality Assurance

Full control of the entire chain, 0 compromise on quality

From concept communication, design prototyping, mass production manufacturing to quality inspection and shipment, we provide a one-stop service throughout the entire process. You only need to contact us through a single point of contact to efficiently resolve all issues related to product manufacturing, significantly reducing communication and management costs.

HID Tube & LED Tube Manufacturer Quality Assurance

Need help? Complex customization is carried out according to the special requirements of customers

“We are not middlemen; every penny you pay goes directly into the product itself.

With our own raw material production workshops, LED tube production lines, and assembly lines, we eliminate all markups in the supply chain, offering you the advantage of factory-direct pricing. Compared to similar products, you save over 15% on costs.

✓ Customer benefits: Access fishing lights comparable to Japanese and Korean brands, with competitive end-user pricing and greater profit margins.

✓ Secure a competitive edge in the market and maintain momentum during peak seasons!

"Engineers and workshops are separated by just a wall:

Molds can be adjusted on the same day as sample confirmation, and order inquiries can reach production line managers within 2 hours.

Urgent orders can trigger *dedicated production line insertion*.

Say goodbye to cross-company communication inefficiencies and improve decision-making efficiency by 50%."

✓ Customer benefits: Seize market opportunities and avoid stockouts during peak seasons

✓ We are the only factory in the industry with full vertical integration and control over the entire fishing light supply chain.

✓ We have mature production lines, and our warehouses always have stock available for standard products.

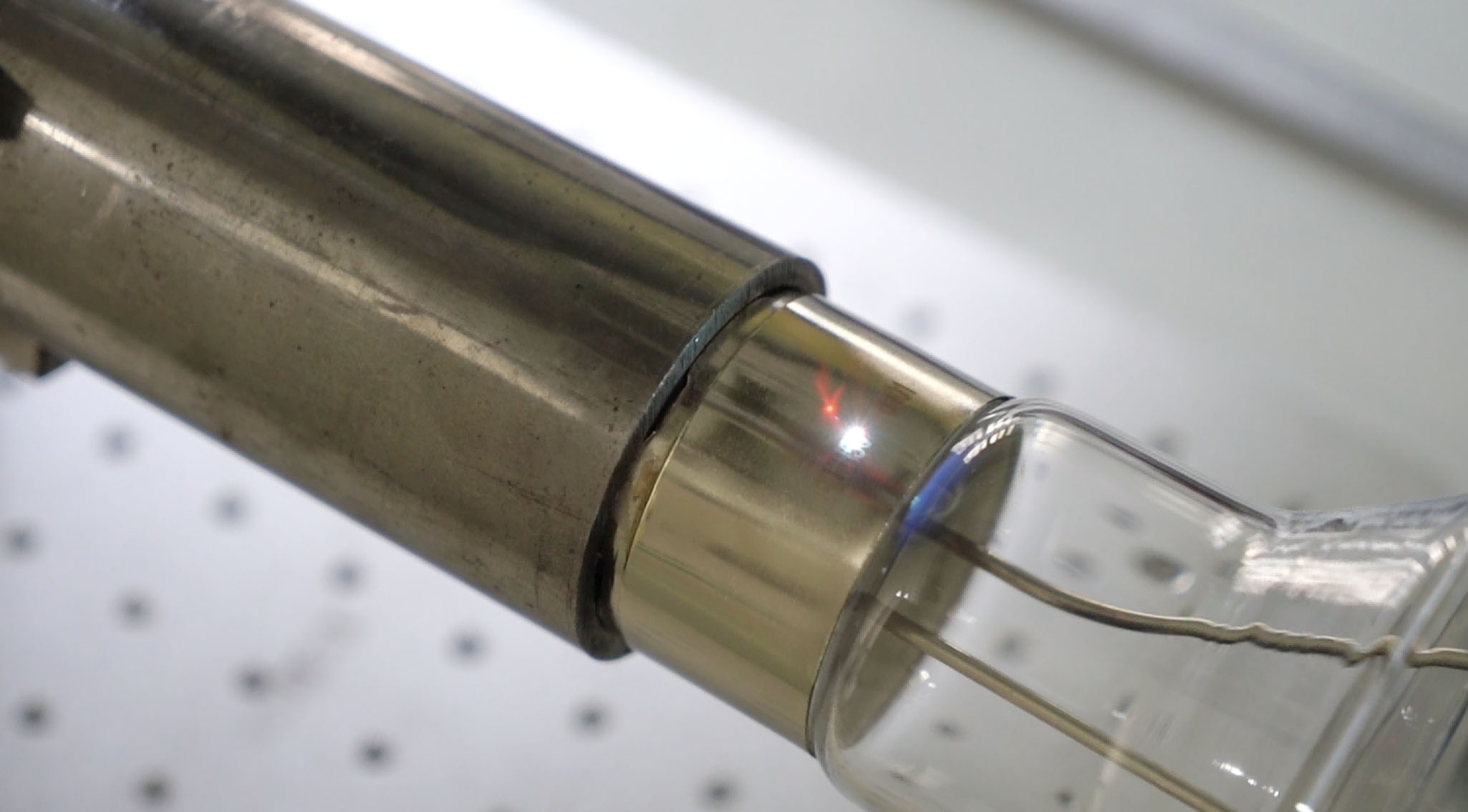

"From quartz tube raw materials to finished lamps, “95% of the process is completed in-house”

The raw material warehouse rejects recycled materials and low-grade materials.

The light tube workshop monitors temperature and humidity in real time (see workshop environment diagram).

Aging tests start at 2,000 hours (see aging test room video).

The “black box” process that trading companies cannot interfere with is completely transparent and controllable here."

✓ Customer benefits: Eliminate the risk of substandard workmanship, reducing return rates by 80%.

“Minimum order quantity of 500 pieces? 300 pieces on an urgent basis? ”Own factory = flexible productivity”

Dedicated sample team supports small batch trial production

Intelligent production scheduling system quickly switches product lines

You don't have to compromise on minimum order quantities, and there is no inventory pressure for new product trials.

✓ Customer benefits: Reduce trial and error costs and respond quickly to market demand

"From blueprints to shipping containers, enjoy dedicated one-on-one project management throughout the entire process:

Sales representatives can directly access production progress in the workshop, while engineers participate in customer complaint handling in real time.

You no longer need to go through the hassle of contacting factory owners, quality control personnel, and order follow-up staff.

Communication steps are reduced by 70%, and problem resolution speed is increased by 3 times."

✓ Customer benefits: Save time and effort, enjoy a hassle-free and efficient collaboration.